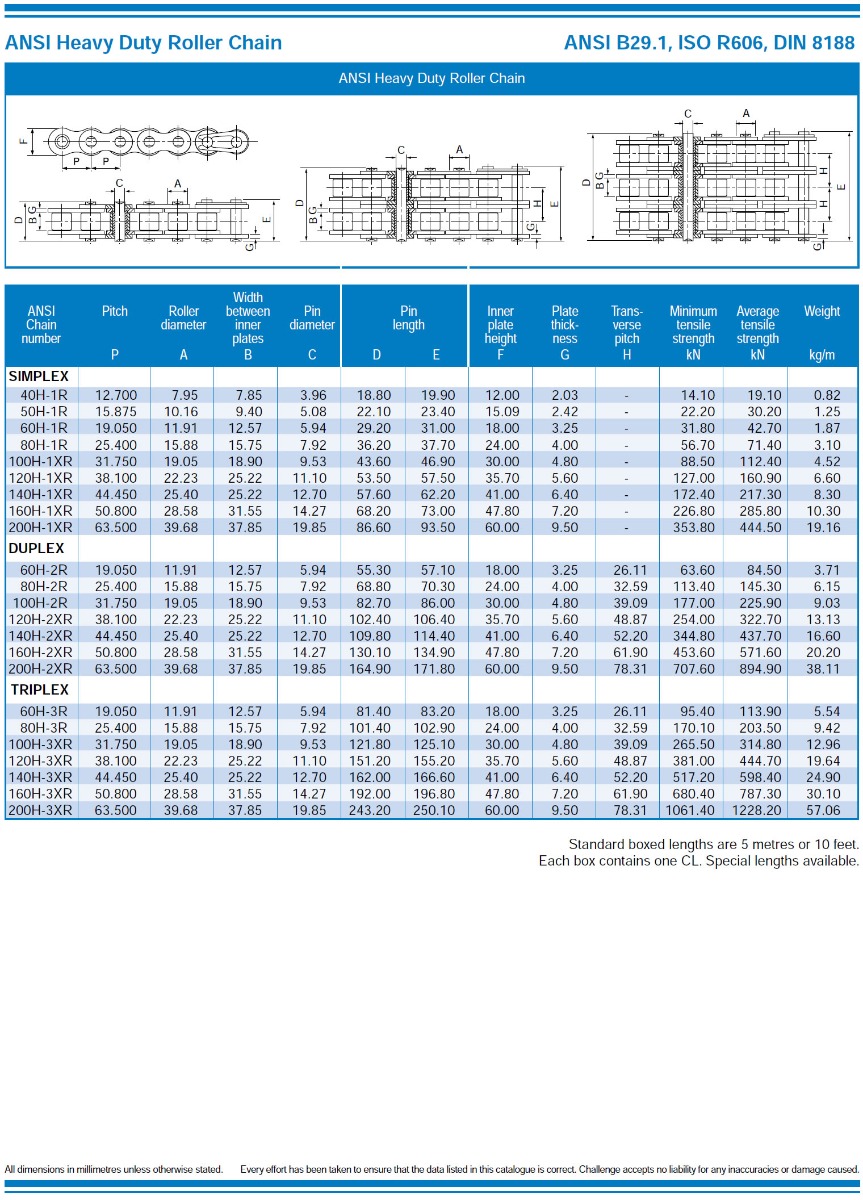

ANSI Heavy Duty Roller Chain

Uprated breaking load ANSI roller transmission chain with increased link plate thickness.

Roller transmission chains are one of the key products that have made Challenge so successful over the last 40 years. With shot peened link plates and ball swaged holes increasing the fatigue resistance, deep wasted link plates upgrading the breaking load and reducing stress, induction hardened precision pins increasing the chains operating life, pre stretching to ensure component alignment with minimal initial elongation and extended service life and optional spin riveting greatly improving link plate security in demanding applications, the Challenge range of precision roller transmission chains are keeping a wide range of industries moving all around the world.

Whether you require British Standard, ISO or the ANSI standard of roller power transmission chain, Challenge is a leading supplier of both chains and sprockets all over the world.

With a wide range of additional supporting products such as taper lock bushes, cone clamps and torque limiters you can be assured that keeping you moving is within our power transmission range.

HIGH FATIGUE RESISTANCE

Due to the high loads transmitted by transmission roller chain, fatigue failure is a common occurrence especially when shock loading is present within the application. Our roller chain not only has ball swaged holes to ensure accurate chain pitch (and therefore even loading around sprockets) but ball swaging and shot peening of the links develops compressive stresses. This actively resists the cracks that cause fatigue failure from initialising and propagating through the link plates which helps to ensure the longest possible service life.

ATTACHMENTS AND SPROCKET STOCKS

A key advantage to Challenge roller chains is our global stocks and expert local support. We hold simplex, duplex and triplex chains, a wide range of attachments and connecting links (A, K SA, SK,WA, WS, WK etc) and a wide selection of sprockets, which are available to take our full range of taper lock bushes; allowing flexibility on shaft size with quick and simple fitting or with a pilot bore for final machining.

Note

All chain coils/lengths are supplied with a standard connecting link.

Manufactured to Standards; ANSI B29.1, ISO R606, DIN 8188

Unit of Sale; 5m Box