LH / BL Series Leaf Chain

BL series leaf chains are heavier duty and often offer a better working life than the AL and LL series of leaf chains. They share similar link profiles, plate thickness and pin diameter to ANSI roller chains, except the leaf chains dimensions are as per the next pitch up in the ANSI transmission chain series.

Leaf chain is a simple form of chain that offers higher tensile strengths and a narrower overall width when compared to standard power transmission chains. Leaf chains are composed of interlaced link plates and pins, but they do not include a bush or a roller. The outer link plates offer a tight interference fit to prevent the pins from rotating, with the leaf chains running over sheaves rather than sprockets.

Due to their increased tensile strength, impact resistance and fatigue resistance, leaf chains or commonly used in lifting and material handling applications. These applications include but are not limited to lifts and hoists, forklift trucks, boom trucks, counter weight systems, machining systems and elevators.

Note

All chain coils/lengths are supplied with a standard connecting link.

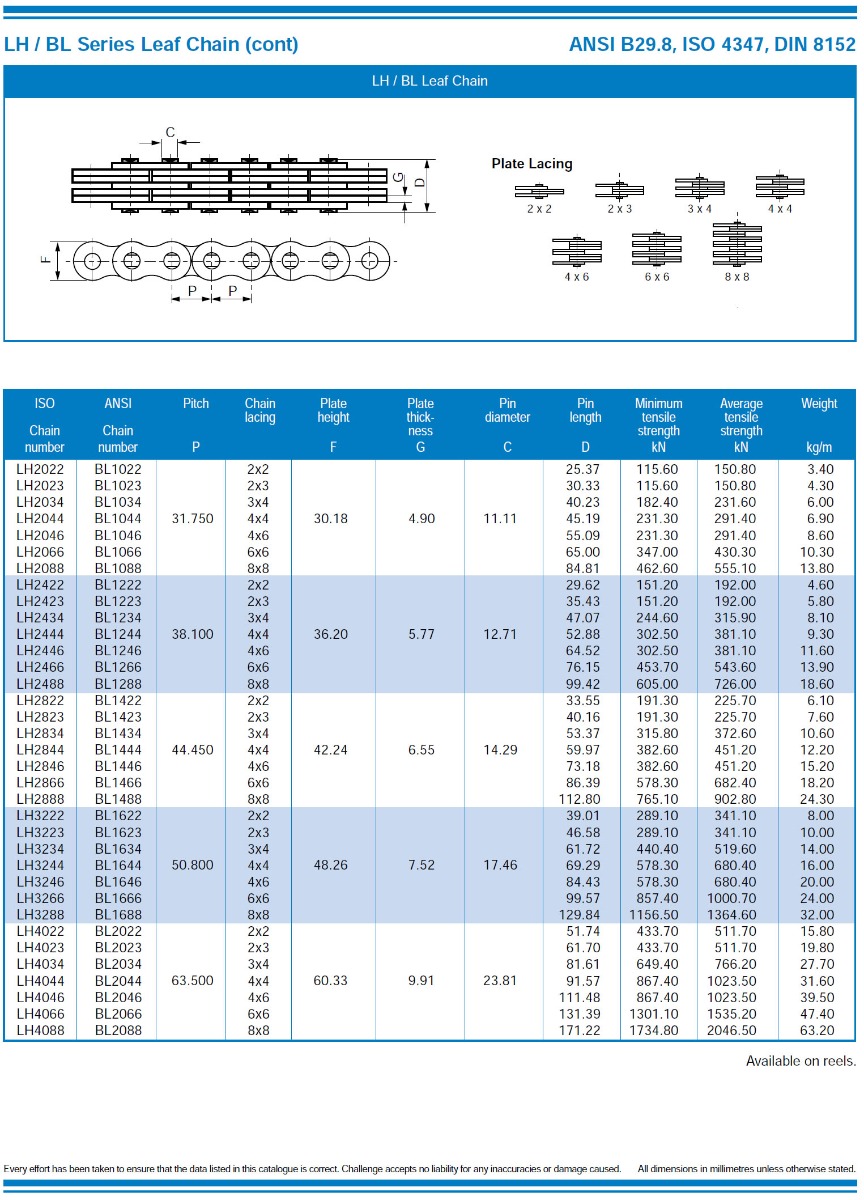

Manufactured to Standards; ANSI B29.8, ISO 4347, DIN 8152

Unit of Sale; CL box