Worm Gear Units

Helical gear Worm Gear Units are a common method of speed reduction throughout industry. Their simplicity, speed reduction capability compared to size, silent running and good torque transmission properties have ensured their success. Ratios of up to 5000:1 can be achieved by coupling multiple worm gears while torque transmission can range from 1Nm up to 3300Nm. There are also several methods for mounting Worm Gear Units, either foot mounting or by using D5 or B14 flanges.

Performance

The performance given in the catalogue correspond to mounting position B3 or similar, ie. when the first stage is not entirely immersed in oil. For other mounting positions and/or particular input speeds, refer to the Tables that highlight different critical situations for each size of reduction unit.

Avoid applications where even partial immersion of the reduction unit is required.

The maximum torque (*) that the gear reducer can support must not exceed two times the nominal torque (f.s.=1) stated in the performance tables.

(*) intended for momentary overloads due to starting at full load, braking, shocks or other causes, particularly those that are dynamic.

Technical Considerations

It is also necessary to take due consideration of and carefully assess the following applications by calling our Technical Service:

• As a speed increaser.

• Use in services that could be hazardous for people if the reduction unit fails.

• Applications with especially high inertia.

• Use as a lifting winch.

• Applications with high dynamic strain on the case of the reduction unit.

• In places with T° under -5°C or over 40°C.

• Use in chemically aggressive environments.

• Use in a salty environment.

• Mounting positions not envisaged in the catalogue.

• Use in radioactive environments.

Versions

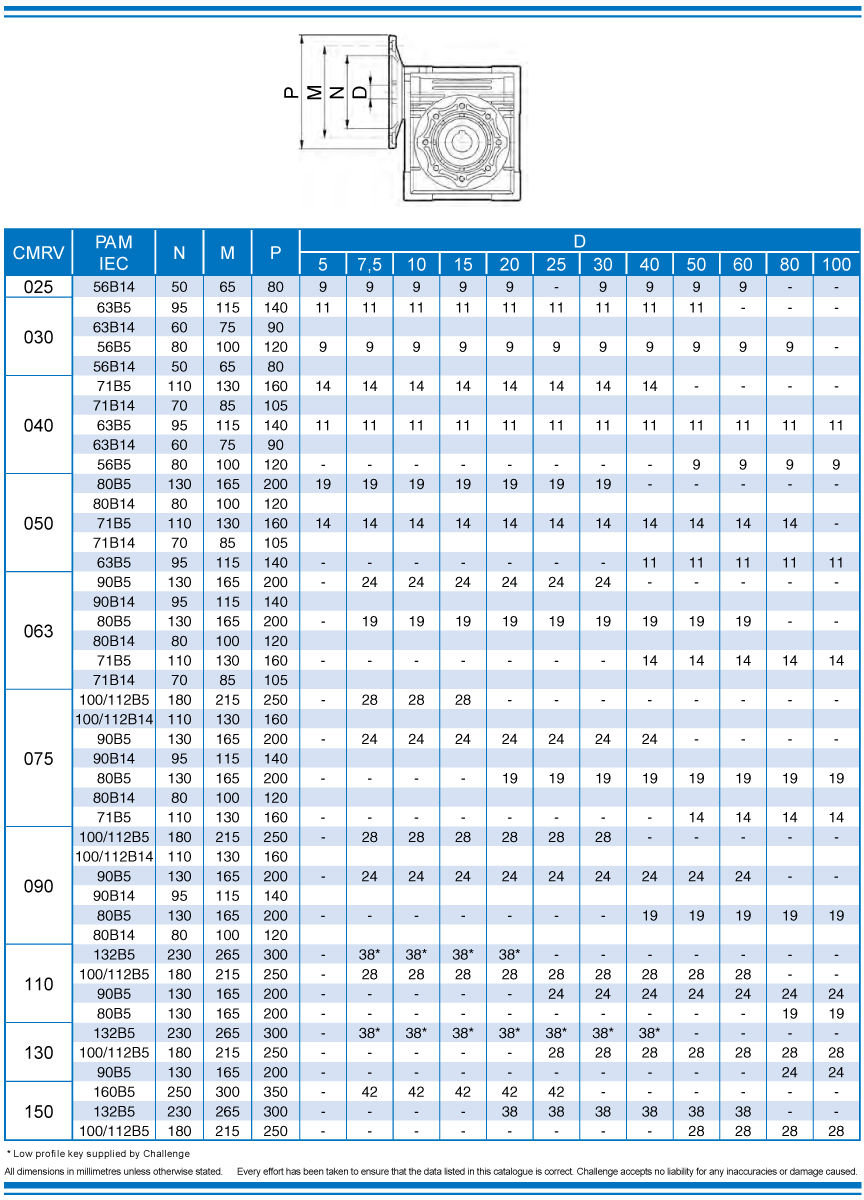

• CMRV 025-150

• CMRV-CMRV

• PC-CMRV

• CRV 030-150

• CRV-CMRV

Unit of Sale; Per Unit