Interchangeable with the Fenner SMSR and Sumitomo HSM for the equivalent model size and gearbox ratio. Grip Loc output hubs are also available.

Metric SMSR Range

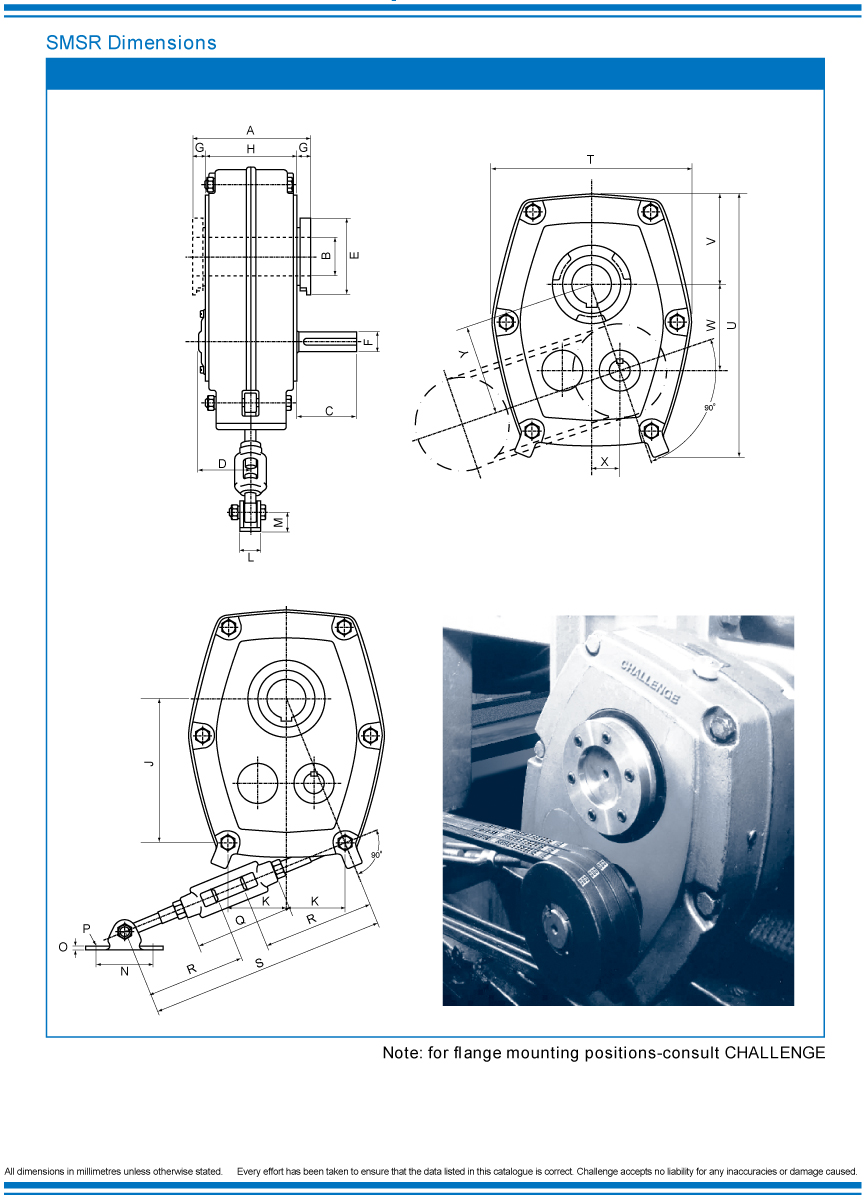

Shaft Mounted Speed Reducers offer a flexible speed reduction solution due to their combination with belt drives, offering ratios in excess of 150:1. Challenge SMSR torque arms offer not only easy installation, but also allow the belt to be kept tensioned without having to move the motor or other prime mover. The SMSR’s themselves are offered in 3 ratios; 5:1, 13:1 and 20:1 which can accommodate driven shafts ranging from 25mm up to 150mm diameter. Maintenance is also an important consideration with our SMSR’s. Not only do we use standard bearings which are easily available globally, but Challenge can also supply all of the components that are used within the unit.

Simple Construction – Main Components

• Casing.

• Output hub, gear, seals and bearings.

• Intermediate shaft, gears, seals and bearings.

• Input shaft, gear, seals and bearings.

Fully Serviceable

Please see our catalogue for maintenance part product codes.

Bearings used are standard and available around the world.

Ease of Lubrication

There are four plugs on SMSR’s to cover lubrication in all available mounting positions:-

• Filler

• Level

• Drain

• Redundant

Depending on which of the 4 mounting positions is used, a different plug can perform a different role i.e. a filler in position 1 becomes the drain in position 2.

Backstops

All SMSR’s are available with backstops, although it is not advsied to use a backstop on the 5:1 ratio SMSR’s.

Backstops are fitted behind the cover plate on the opposite end of the input shaft.

Reducing Bush Locking System

The Challenge reducing bush locking system allows multiple driven shaft sizes to be used with a single model of SMSR. The reducing bush locking system is simple to fit but requires keyways so many customers have now switch to the Grip-Loc system.

Challenge Grip-Loc Locking System

• Has sufficient torque transmitting ability to avoid the need for conventional shaft keys.

• Reversible assembly.

• Obviates problems caused by the usual operating environment and atmospheric conditions.

• By virtue of the design, Grip-Loc prevents the onset of fretting corrosion, which often causes problems with more conventional mounting systems.

• Much simpler to install and remove than keyed assemblies.

• Fits standard shafts with h11 tolerances.

Unit of Sale; Per Unit